Elang Air Compressor All Model

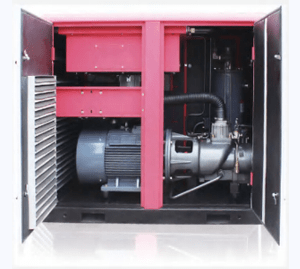

BELT DRIVEN SCREW COMPRESSOR

Structure

All internal pipes are seamless carbon steel, giving the machine a sleek appearance and greatly extending service life.

Neat internal layout saves space.

Motor

High‑efficiency motor (same supplier as Atlas Copco & Ingersoll Rand China).

Protection class IP54/IP55; insulation class F.

Optional ABB or Siemens motors available.

Oil Filter

German MANN oil filter removes impurities from the lubricating oil.

Easy to replace, leak‑proof design.

Belt Cover

Specially designed cover prevents accidental contact with the running belt.

Quick‑release for easy maintenance.

Acoustic Enclosure

Fully enclosed mute‑box design with sound‑absorbing sponge.

Reduces noise by 3–5 dB(A).

COMBINED SCREW COMPRESSOR

Combined Screw Air Compressor Series: The combined screw air compressor integrates a screw compressor, air dryer, fine filter and air tank into one unit, making installation, operation and relocation—by the same user—effortless. Once the air passes through this integrated system, its quality is significantly enhanced to meet the varied process requirements of different industries. With its sleek appearance, stable performance and cost‑effective installation, this series has become one of our key export offerings.

Integrates a screw compressor, air dryer, fine filter, and air tank for easy installation, operation, and mobility.

Delivers high‑quality air that meets diverse industrial process requirements.

Boasts an attractive appearance, stable performance, and cost‑effective installation.

One of our key export series.

Superior Air Inlet

Superior Air Inlet and Filter System combines a customized two‑stage dust‑removal and filtering design that delivers up to 99.9 % efficiency in heavy‑duty environments. By drawing in ambient‑temperature air, it lowers the discharge temperature by 3–10 °C, extending component life. A German MANN oil filter further purifies lubricating oil, safeguarding the oil circuit and boosting overall service life.

Energy‑Efficient Cooling Method uses high‑conductivity aluminum fins and copper coils to optimize heat transfer. The cooler is mounted separately from the hot internal chassis so that fans draw in cool outside air—saving over 30 % energy and reducing the outlet air temperature by 3–8 °C.

Optimum System Design is fine‑tuned by our technicians to minimize operational errors and improve air delivery efficiency. Its three‑stage air‑oil separation (centrifuge, gravity, filter) lowers pressure drops and cuts energy use, while ensuring oil carry‑over stays below 3 ppm for high‑quality output.