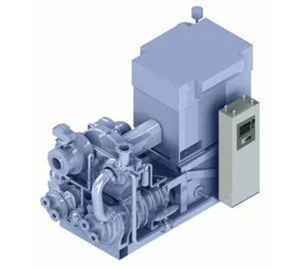

Elang Centrifugal Air Compressor

AIR END

Gearbox

Horizontal split‑type design allows easy access for bearing and shaft‑seal maintenance. A thrust collar replaces thrust bearings, simplifying the structure and boosting transmission efficiency and reliability.

Cooler

Water‑in‑tube and air‑in‑shell construction ensures straightforward upkeep. Its patented variable‑section design optimizes cooling and drainage, while a self‑seal feature enhances reliability. A rugged lager bearing lets it withstand extreme conditions, and the integrated heat‑recovery option improves overall energy utilization.

Diffuser

Converts the compressor’s kinetic air energy into pressure with high efficiency, aided by an impeller‑matched design. Surface hardness is increased to HV1300 via MA treatment, tripling the diffuser’s service life.

Labyrinth Seal

Non‑contact gas and oil seal with a labyrinth profile—no abrasion, minimal wear and zero instrument‑air consumption. The horizontal split allows quick inspection and maintenance, delivering long life and low upkeep.

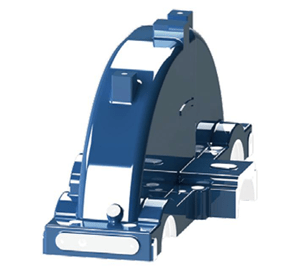

Inlet Guide Vane

Smooth, highly efficient airflow adjustment via a fork‑type mechanism with protective cover for safety and dust prevention. Provides precise control and reliable performance.

CENTRIFUGAL COMPRESSOR LEADS THE FUTURE

| Compressor Type | Air Flow | Pressure Range | Key Features |

|---|---|---|---|

| Centrifugal Compressor | > 30 m³/min (medium–high flow) | Low / Middle / High | Multi‑stage design for high isothermal efficiency; simple structure and low maintenance. |

| Screw Compressor | < 40 m³/min (small–medium flow) | Low / Middle | Robust rotary‑screw mechanism; reliable performance with moderate pressure. |

| Piston Compressor | N/A (flow varies by model) | High | Reciprocating piston delivers high pressure; suitable for special gases. |

SMART ENERGY SAVING CONTROL MODE

Control Modes via Inlet Guide Vane (IGV)

The compressor can operate in multiple modes—Constant Pressure, Constant Pressure + Auto Dual, and Self‑Balance—by modulating the IGV opening. In Constant Pressure Mode, the IGV adjusts to maintain outlet pressure; in Auto Dual Mode it switches between loading/unloading and constant‑pressure control to prevent surge; and in Self‑Balance Mode it uses the blow‑off valve (BOV) alongside IGV for fine surge protection and stable operation across the full flow range.

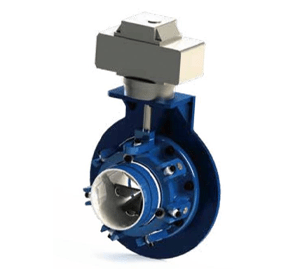

Advantages of IGV vs. Butterfly Valve

Using an IGV yields 7–9 % higher efficiency compared to a butterfly valve because it provides preswirl flow aligned with the impeller direction. It also offers a wider, smoother turndown range, allowing precise airflow adjustments during changing load conditions.

0–100 % Flow Range

Thanks to a highly reliable BOV that can load/unload up to 200,000 cycles per year, the compressor manages flows from 0 to 100 % of design capacity without compromising stability or service life.

Siemens PLC Touch‑Screen Control System

The integrated Siemens “+7″ PLC touch screen provides an intuitive interface for auto‑dual, constant‑pressure and self‑balance modes. It displays and lets you set all running parameters, supports multiple alarms/trip conditions, offers anti‑surge and surge‑prediction functions, and communicates via DH⁺, Modbus, Profibus or Ethernet for seamless integration into your DCS.